Continuous Sterilizer

for HDPE and PP Bottles

Continuous Sterilizer for HDPE & PP Bottles

For the secondary high-temperature sterilization of products packaged in HDPE/PP bottles, OUSI revolutionized the traditional batch sterilization process, and developed a continuous sterilizer specially for HDPE/PP bottles.

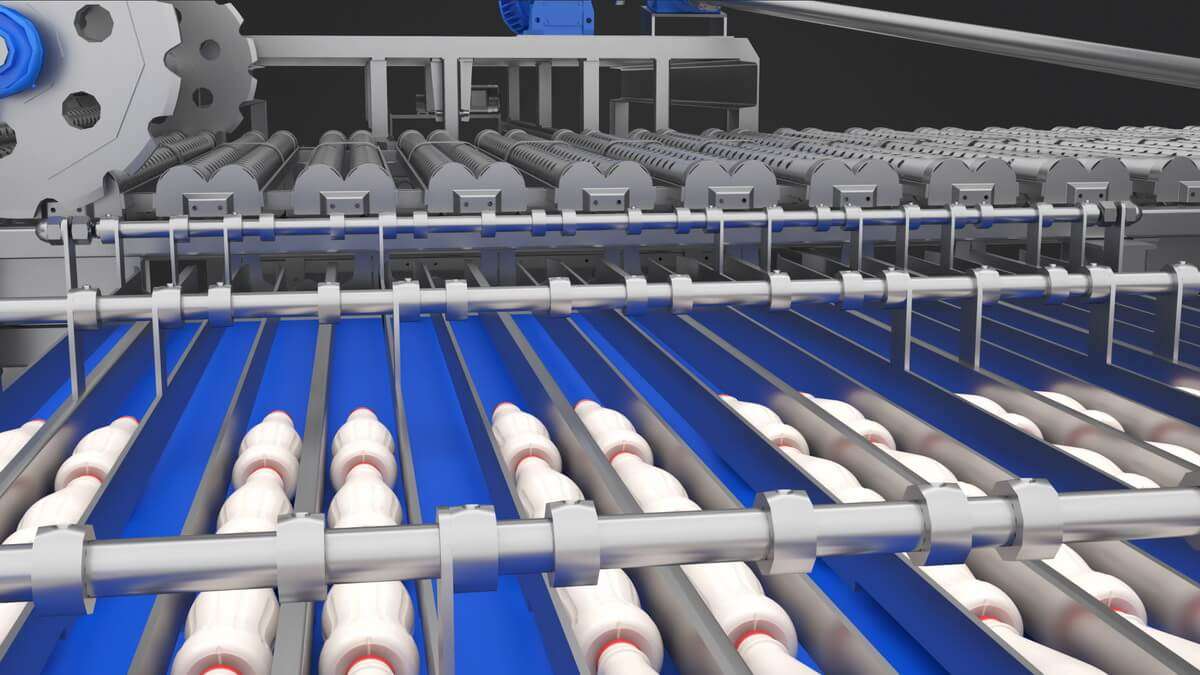

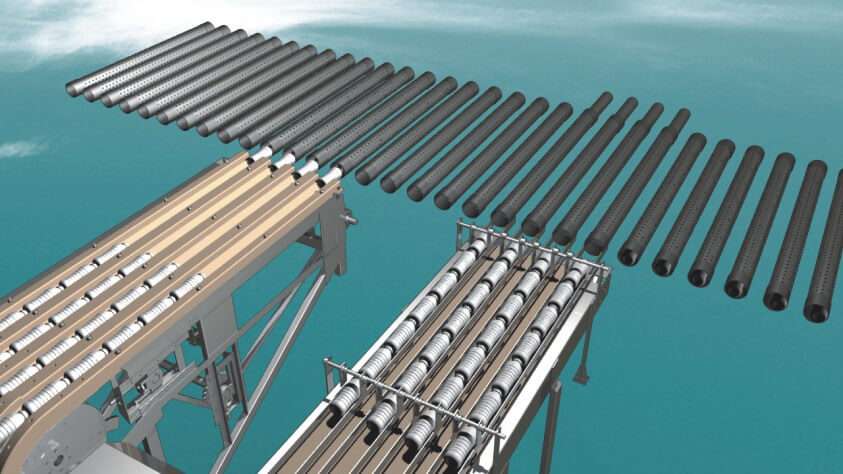

Loading & Unloading

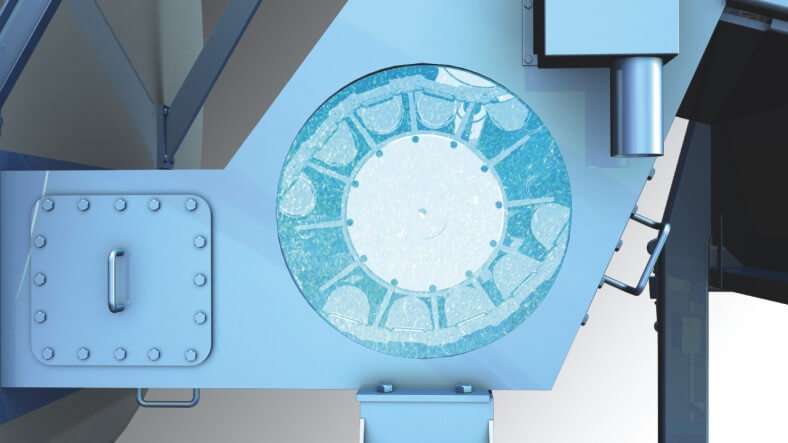

Water-lock Valve

Features

The sterilizer directly connects to the former filling machine and the subsequent packaging line, to realize seamless connection from filling, sterilization to packaging. This meets the requirements of intelligent manufacturing and digital production lines.

High production capacity. The single-carrier sterilizer is 450 bottles per minute or more. The duo-carrier sterilizer is 500 bottles per minute or more.

In the sterilization process, the bottle carriers keep moving and rotating, and the products are stirred, which makes all product parts heated evenly, thus avoiding overheating the product.

The hydraulic fan ensures that the temperature in the vessel is evenly distributed, which greatly improves the heat transfer efficiency so that the required sterilization temperature can be reached in a shorter time.

The sterilization temperature is adjustable from 85°C to 140°C.

The pressure in the vessel is adjustable to avoid deformation of the bottles.

The sterilizers can be tailor made according to specific technical requirements, sterilization process parameters, and capacity requirements to obtain the most effective, reliable, consistent, and energy-saving solutions.

Get Quote, Help, Anything

Talk to our experienced sterilization experts to learn more about how we can help.

Fill in our contact form and we will reply your message within 24 hours.